Toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing;[1] Material toughness is defined as the amount of energy per volume that a material can absorb before rupturing. It is also defined as the resistance to fracture of a material when stressed.

Toughness requires a balance of strength and ductility.[1]

Contents |

Mathematical definition

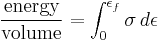

Toughness can be determined by measuring the area (i.e., by taking the integral) underneath the stress-strain curve[1] and its energy of mechanical deformation per unit volume prior to fracture. The explicit mathematical description is:

Where

is strain

is strain is the strain upon failure

is the strain upon failure is stress

is stress

Another definition is the ability to absorb mechanical (or kinetic) energy up to failure. The area covered under stress strain curve is called toughness.

If the upper limit of integration up to the yield point is restricted, then the energy absorbed per unit volume is known as the modulus of resilience. Mathematically, the modulus of resilience can be expressed by the product of the square of the yield strain divided by two times the Young's modulus.

Toughness tests

Tests can be done by using a pendulum and basic physics to measure how much energy it will hold when released from a particular height. By having a sample at the bottom of its swing, a measure of toughness can be found, as in the Charpy and Izod impact tests.

Unit of toughness

Toughness is measured in units of joules per cubic metre (J/m3) in the SI system and inch-pound-force per cubic inch (in·lbf/in3) in US customary units.

Toughness and strength

Strength and toughness are related. A material may be strong and tough if it ruptures under high forces, exhibiting high strains, while brittle materials may be strong but with limited strain values so that they are not tough. Generally speaking, strength indicates how much force the material can support, while toughness indicates how much energy a material can absorb before rupturing.

See also

References

- ^ a b c "Toughness", NDT Education Resource Center, Brian Larson, Editor, 2001-2011, The Collaboration for NDT Education, Iowa State University